With the recent acquisition of the balance of the Yekani assets, Microtronix now operates 50 CNC component placers or pick-and-place machines for service to our customers. Weller’s WXSMART soldering station is an all-in-one solution for any soldering and reworking needs and is currently the most connected, controlled and secured hand soldering system available.Ī micro nozzle is Pillarhouse’s patented 1,5 mm nozzle which helps to solve the challenges of particularly small nozzle requirements in selective soldering.Įven with its compact dimensions and attractive price, this inline selective soldering machine does not require the user to make any compromises in terms of quality and throughput. Weller WXSMART all-in-one smart soldering station Inspekto’s autonomous visual inspection solution

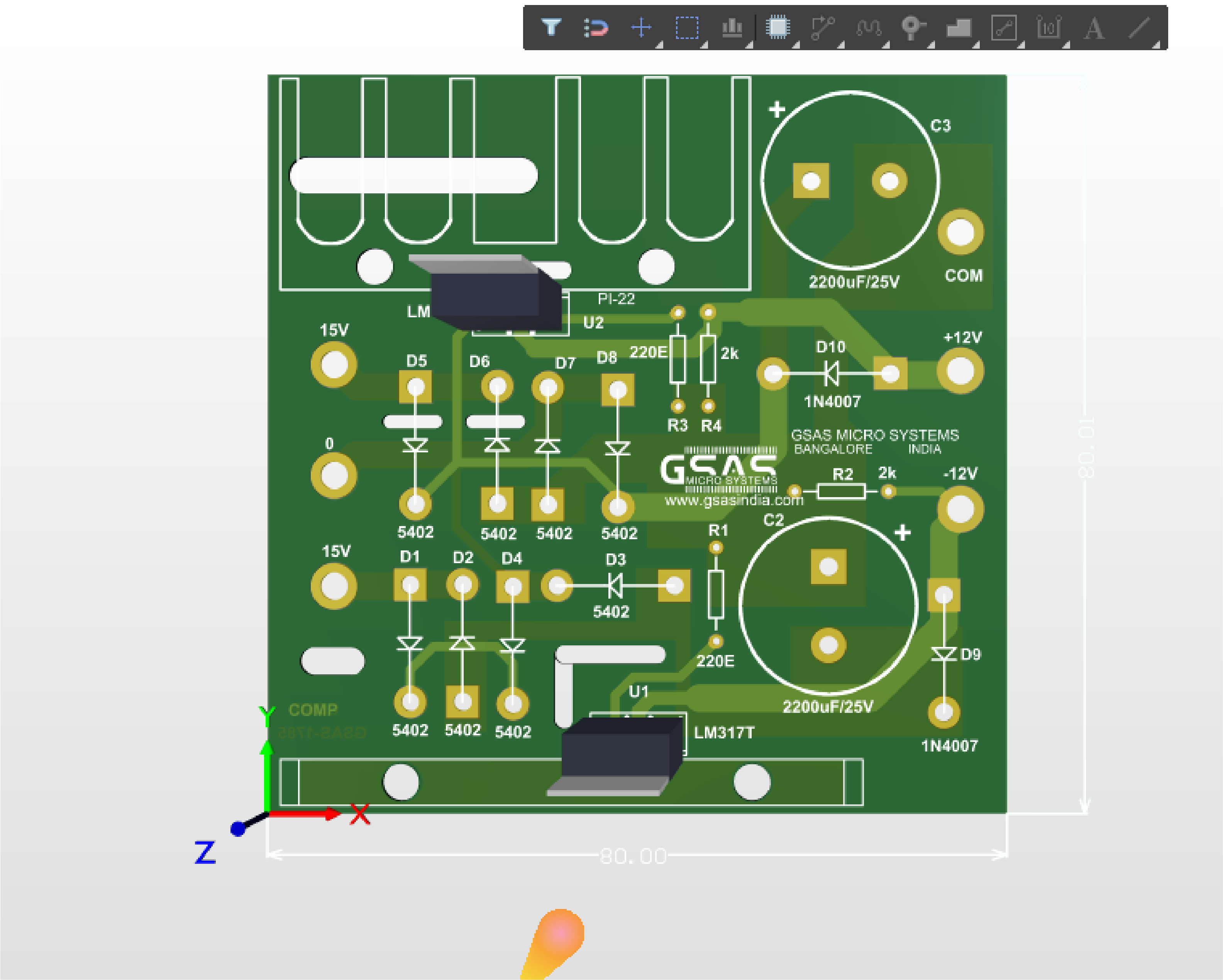

It prides itself on service and support, knowing that having a great relationship with customers means putting them first. The company aims to be a leader in the supply of excellent service and quality production consumables and equipment. Inspekto has launched a new software version of its INSPEKTO S70 autonomous machine vision system, which now offers smart features that guide users in creating and maintaining inspection profiles, and improves usability, process integration and accuracy of inspection. Upgraded autonomous visual inspection solution PCB manufacturers and educators are now able to easily save time and money with the Voltera V-One desktop PCB printer, which allows for rapid prototyping of circuit board layouts. Manufacturing / Production Technology, Hardware & Services Interfacing of power and data is usually done through panel-mount connectors on the rear face of the enclosure.įurther reading: Multi-functional circuit board printer for designers and educators Parts are CNC machined to perfectly support the board from both sides, thus ensuring that it does not experience any mechanical stresses during testing. Unique tapered tooling pins precisely position the UUT and, together with linear guide pins and bushes, ensure highly accurate, repeatable and reliable contacting of test points down to 50 mil (1,27 mm) pitch and probe counts up to 300.Įxperienced engineers carefully customise the design of each and every fixture specifically for the board that is being tested. The fixture uses a sophisticated lifting mechanism to precisely raise a platen containing the spring-loaded test probes from below the unit under test (UUT). It is built with a sturdy aluminium enclosure whose 350 x 300 mm footprint makes it especially suitable for benchtop use. This mechanical bed-of-nails test fixture, according to its maker Test Fixture Technologies, is the most widely used solution for printed circuit board (PCB) testing in South Africa.

0 kommentar(er)

0 kommentar(er)